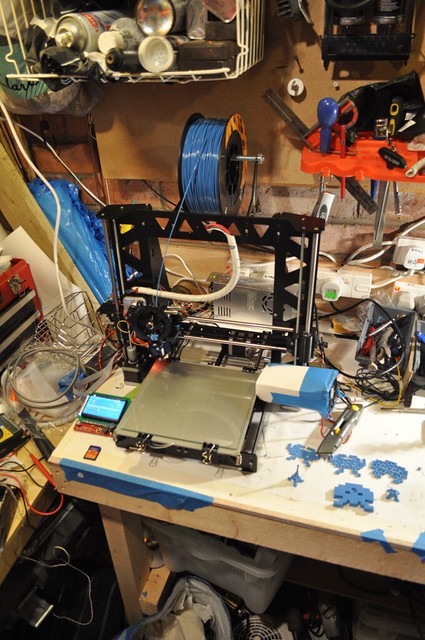

Latest update from me, I got my printer all setup, and calibrated the axis, I ended up with 160 steps/mm for the X and Y axis, 8000 steps/mm for the Z axis and 1942.2716 steps/mm for the extruder. I pushed both my marlin configuration and the Slic3r configuration to github (https://github.com/paulhurleyuk/Marlin and https://github.com/paulhurleyuk/Slic3r).

I then tried a few test prints and got a succession of filament jams, I think for the following reasons (roughly in order);

-

I left the little plastic tube out of the extruder and the filament kinked and jammed

After reassembling the hotend I screwed the heatbreak into the hotend first instead of the heatsink leaving a gap

I had the retraction setting way to high in slicer (10mm) and it was pulling hot filament up into the heatbreak

The wire to the hotend fan broke and the heatbreak got too high

So, I've learned a lot about disassembling my hotend and clearing it out, which generally involves removing the whole hotend, unclipping the fan, unscrewing the nozzle, heatbreak and heatsink, then screwing the heatbreak back into the heater block, heating it and poking the melty filament out, cleaning the hobbed bold and then putting it all back together.

I also tried rubbing a little rapseed oil in a sponge over the filament which seems to have helped as well. I also loosened the filament slightly as the filament holder is a M8 bolt and the reel doesn't spin particularly well on it, at some point I'll add some skate bearings.

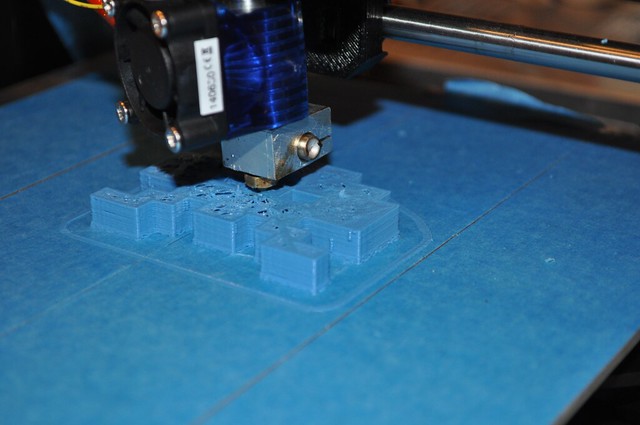

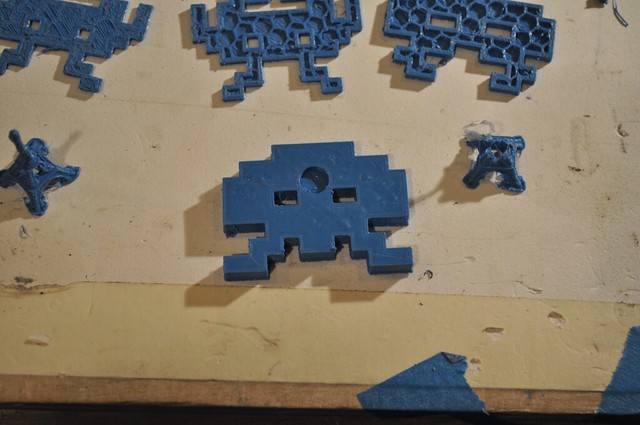

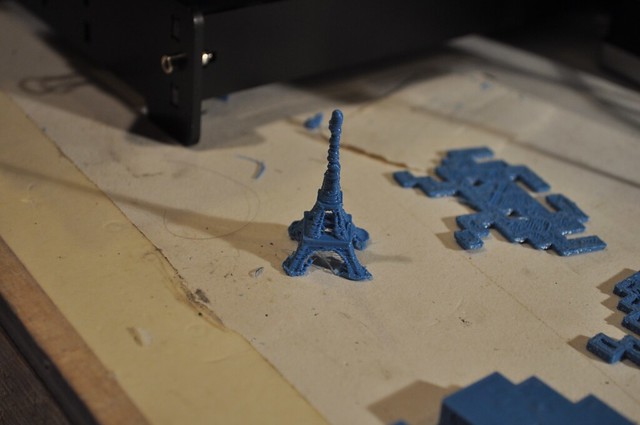

I've now got some successful prints, although they're a little rough;